Penn M.Arch 704 Studio Robert Stuart-Smith: Final Review 6th May 2020

TA: Musab Badahdah

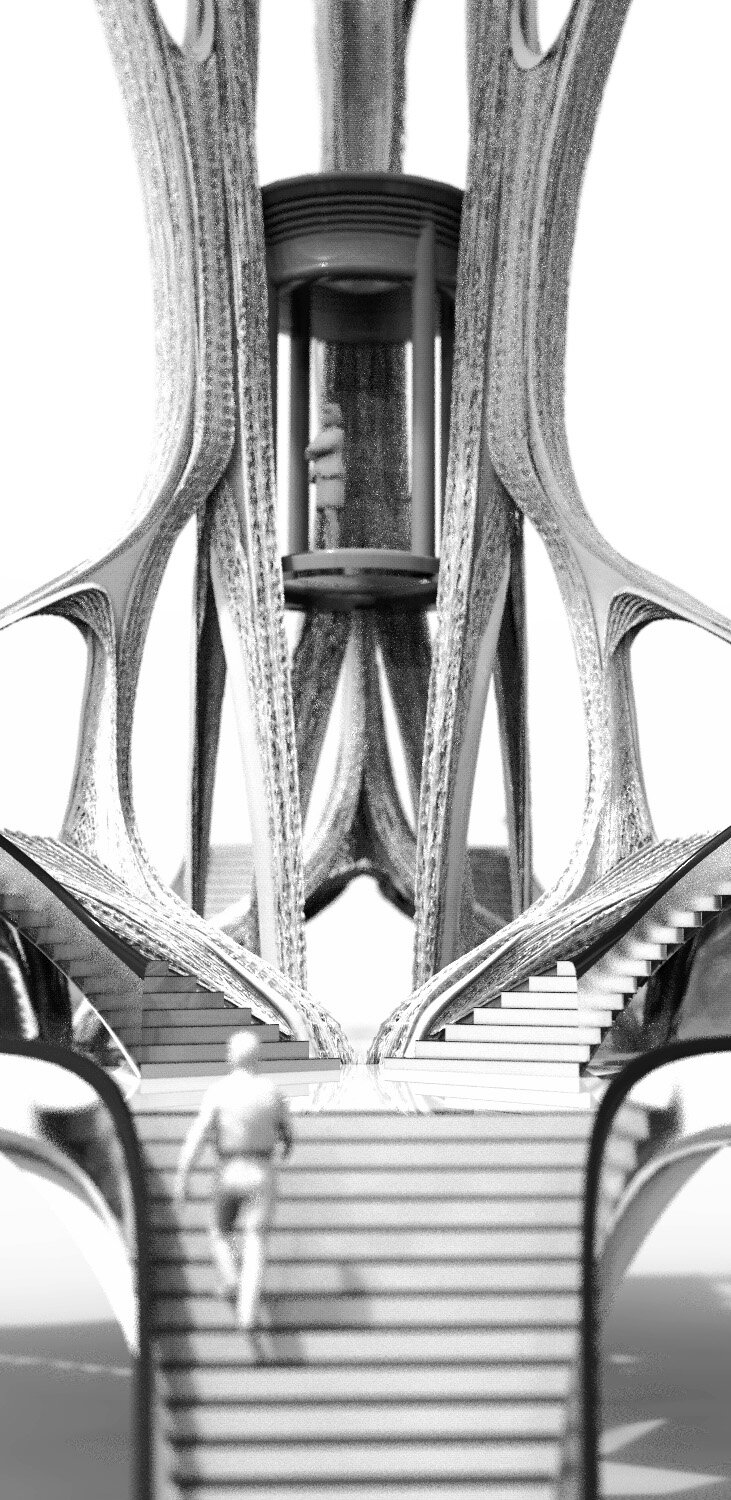

Polyvalent Matter: An Additive Manufactured Architecture

Studio Robert Stuart-Smith

TA: Musab Badahdah

Students: David Forero, Yichao Jin, Zachary Jones, Ian Hoi Yin Lai, Atharva Ranade, Siyi Wang, Tsui-Lun Wang, Yuqing Ye, Jing Yuan, Youyu Zhang, Ruxin Zheng, Zhe Zhong

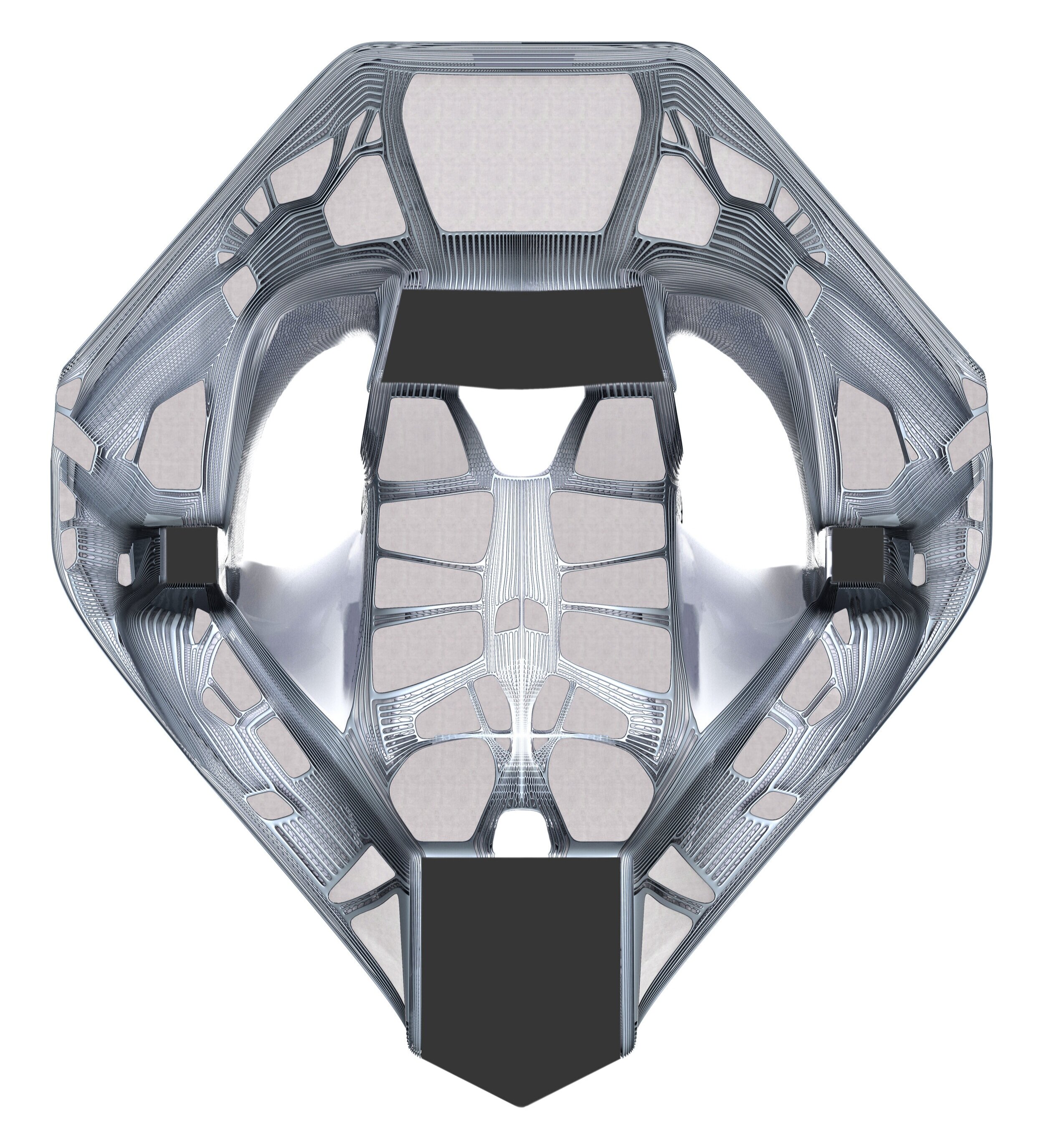

Polyvalent Matter explores an additive manufactured industrial architecture that operates as a form of cultural production, while aiming to integrate material-scales of design-expression as an intrinsic property of formal, spatial and structural order.

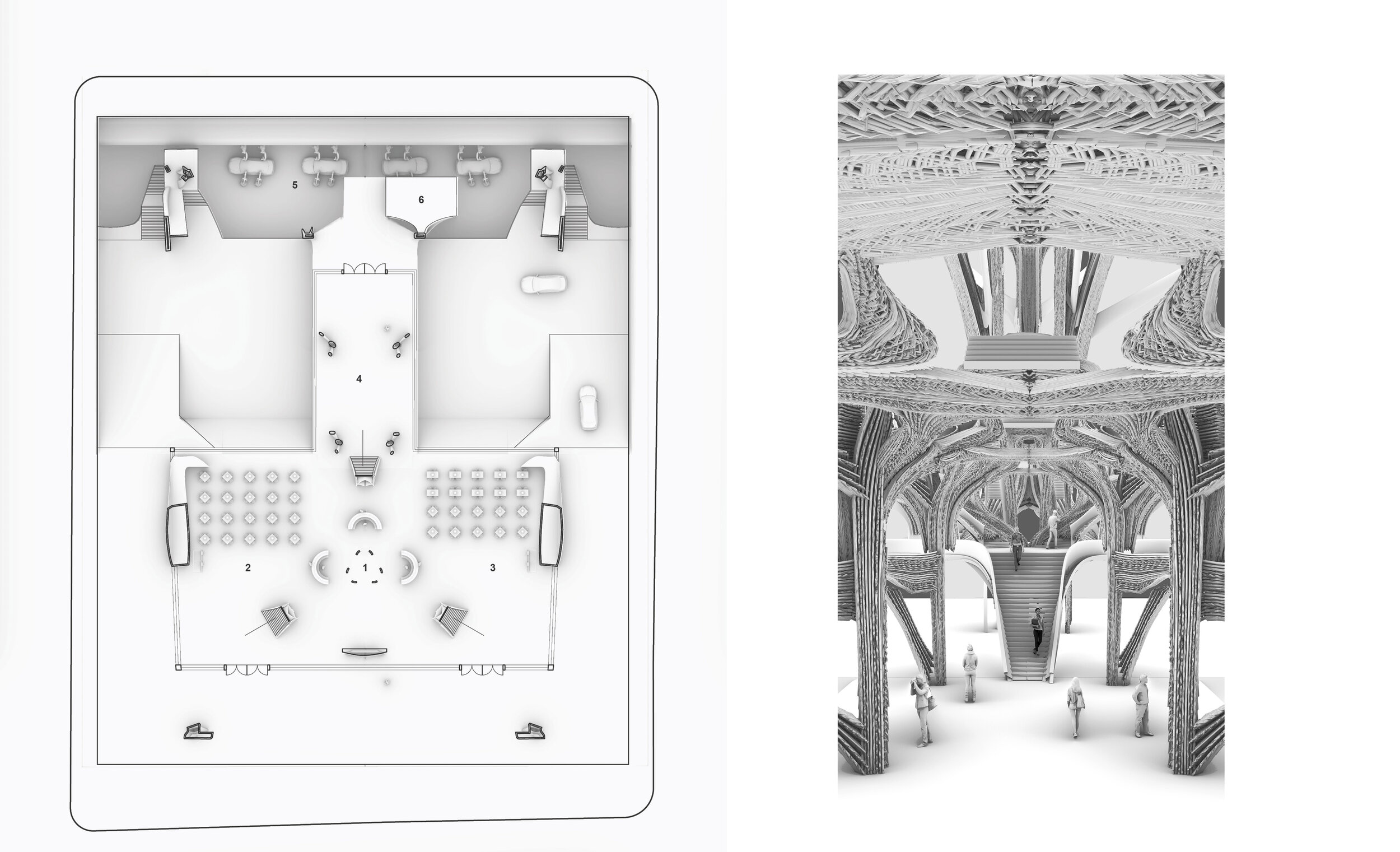

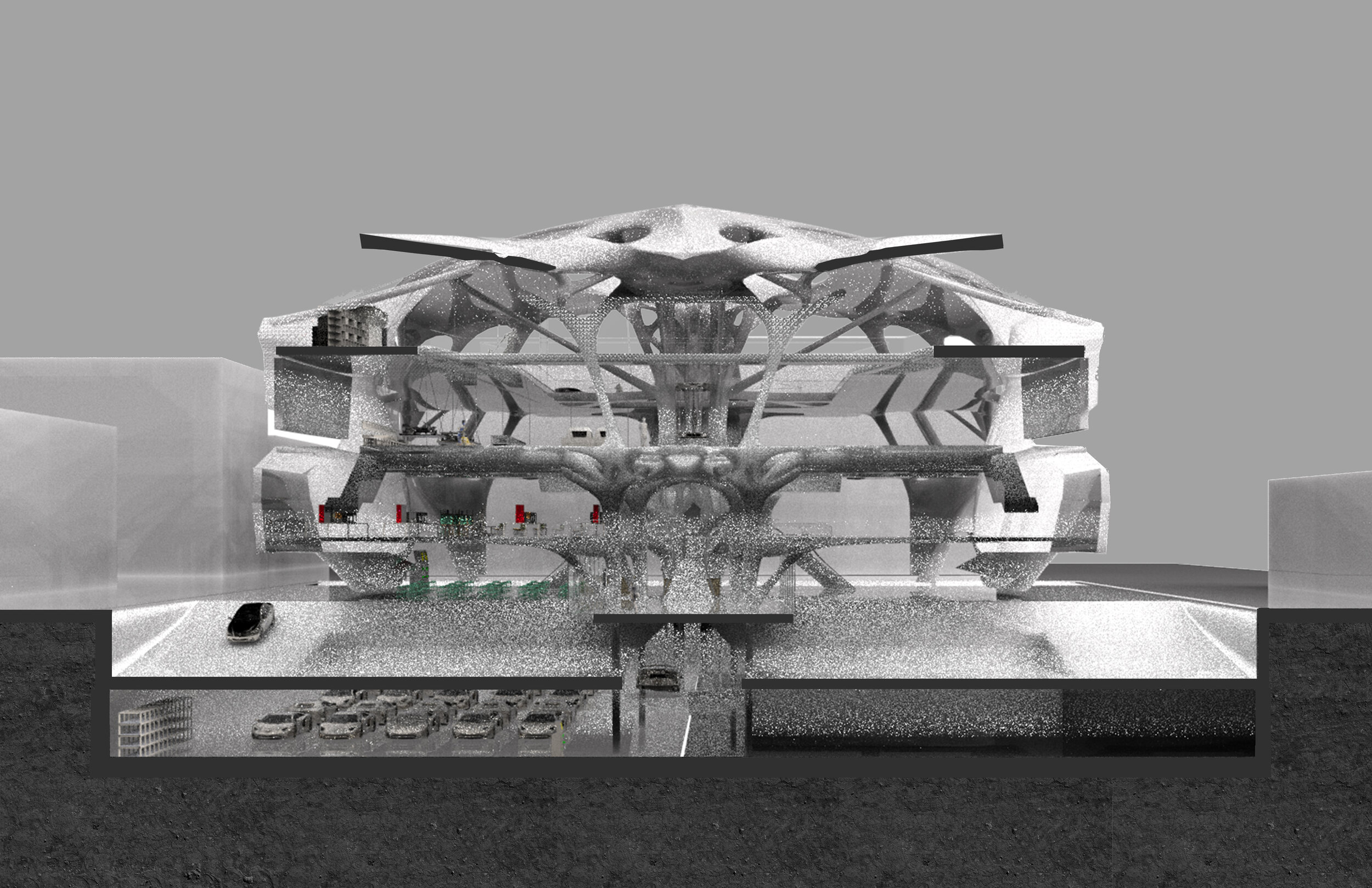

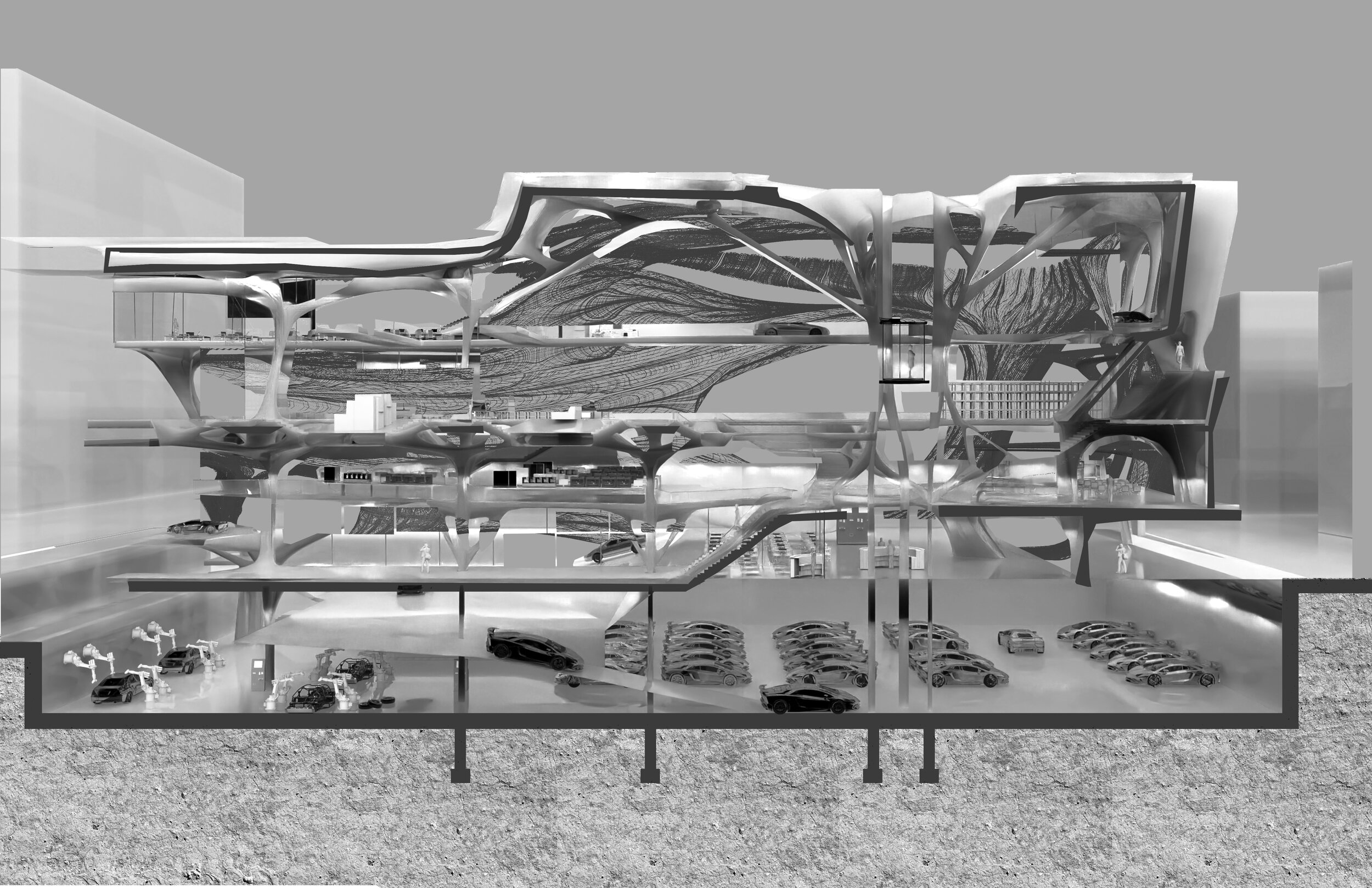

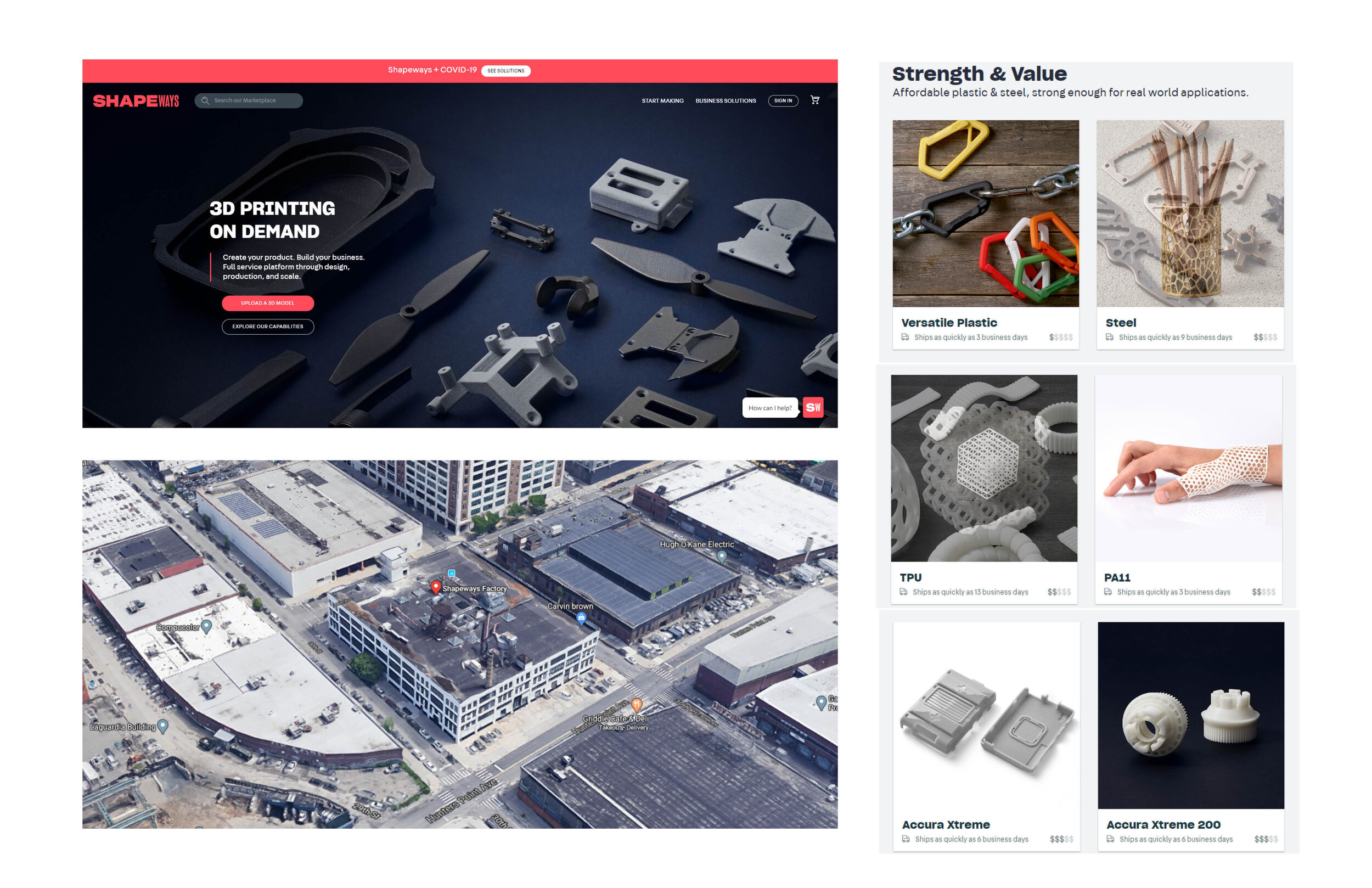

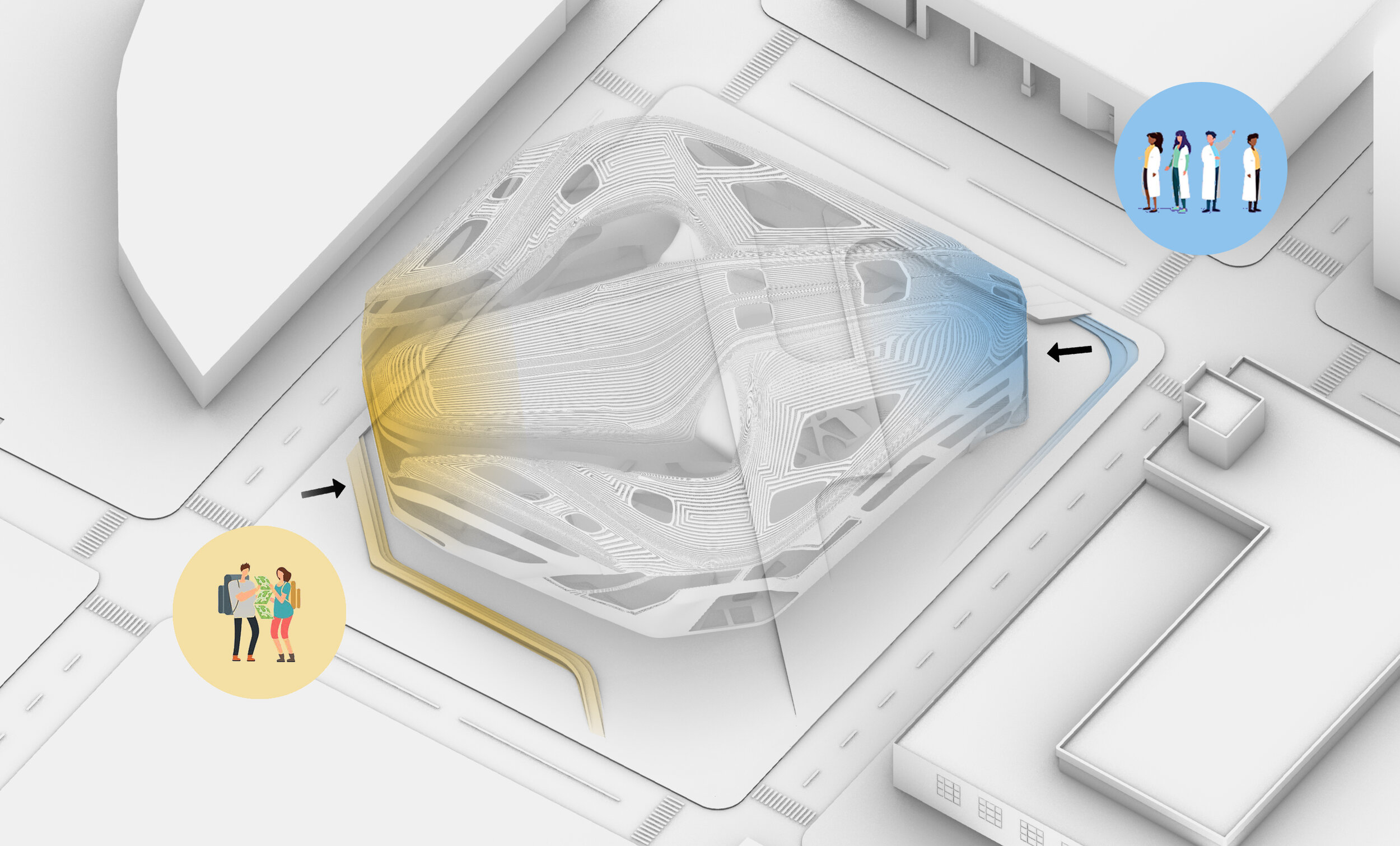

Shapeways Factory-Showroom:

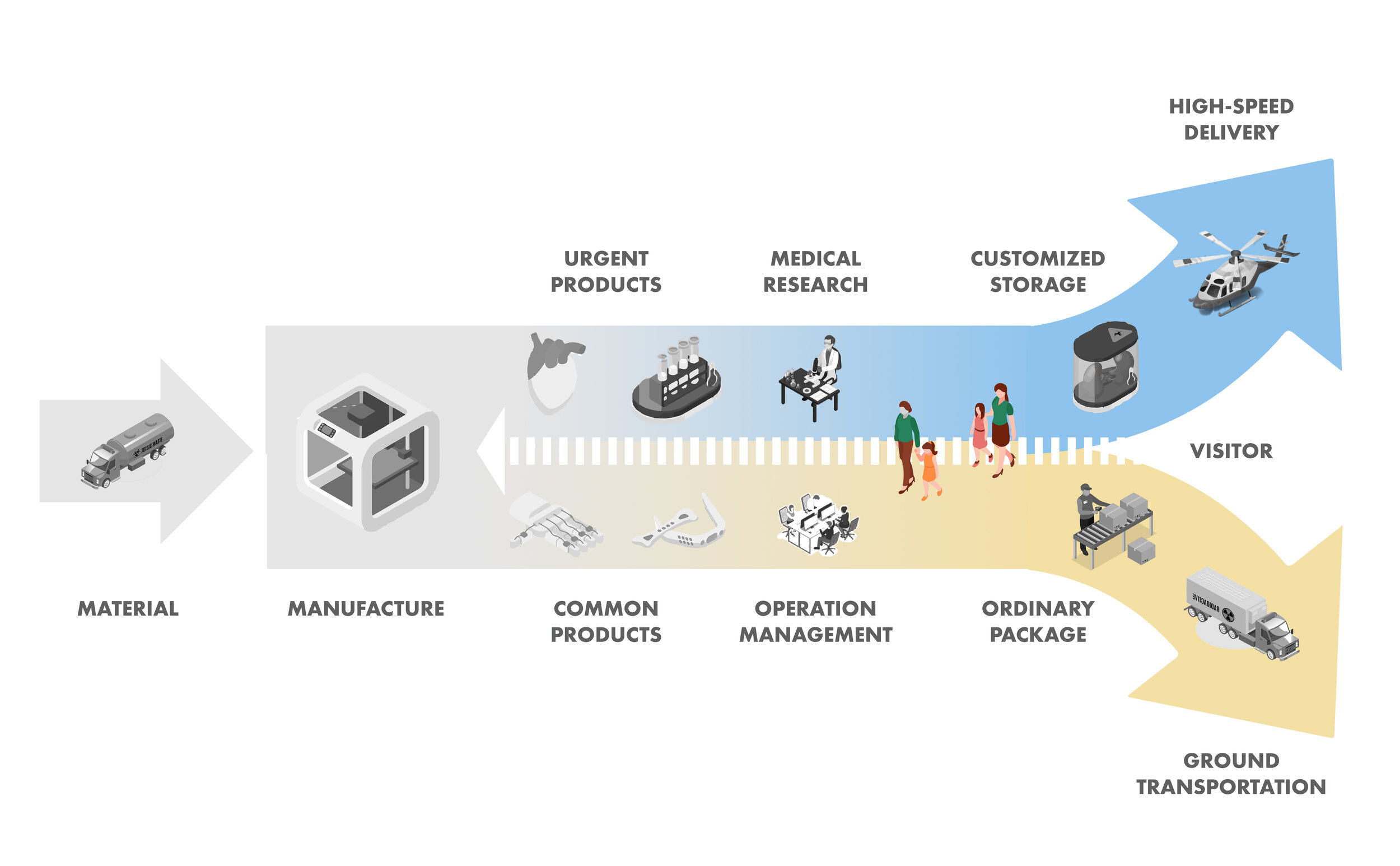

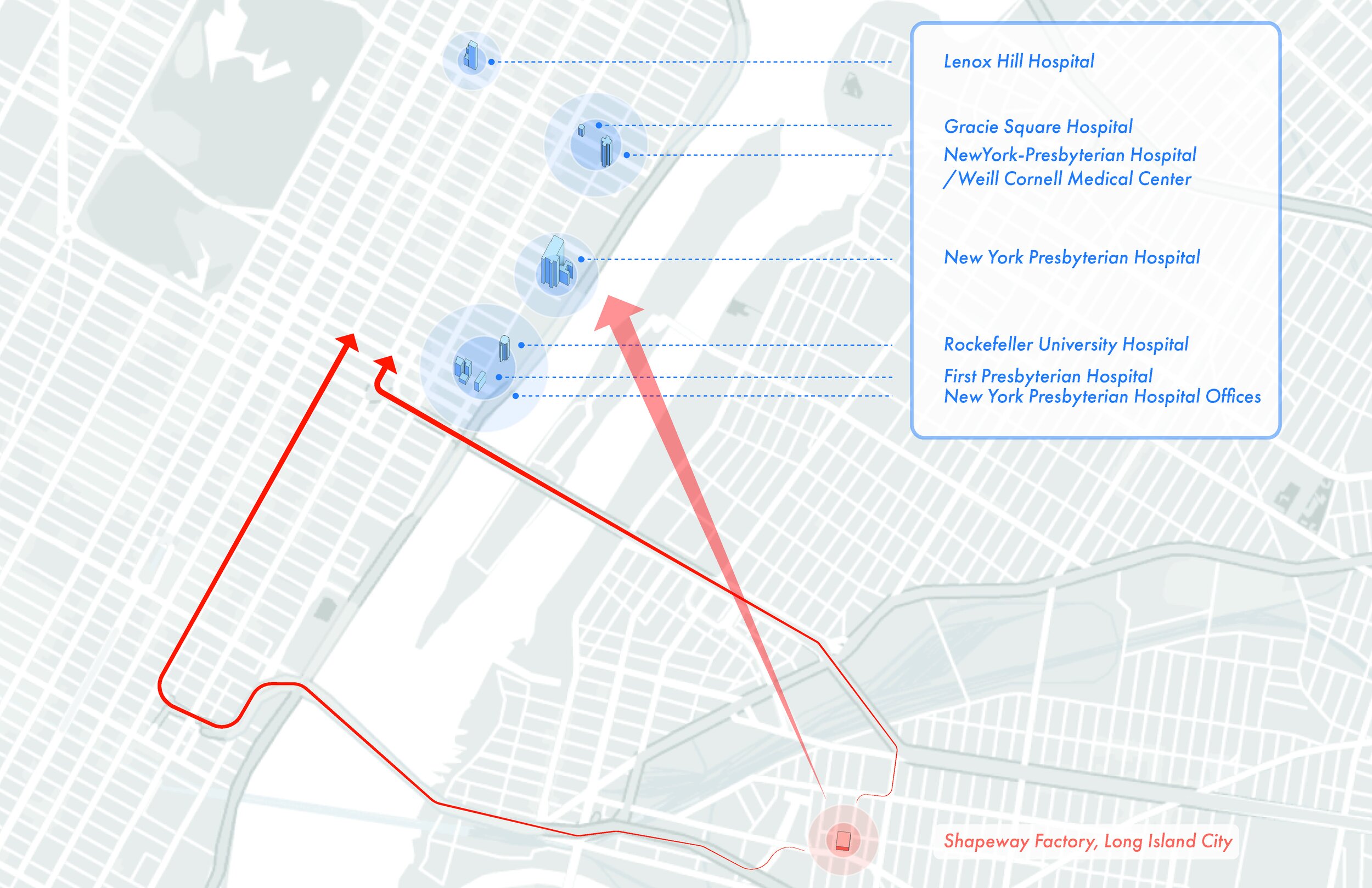

Manufacturing companies are known and valued for their products but also for the quality and identity of the buildings in which these products are made. Factory-showrooms such as Vitra’s Weil-am-Rhein campus operate as both industrial buildings and arenas for public visitation. Marco Zanuso’s design for Olivetti’s Buenos Aires Factory(1964) or Heatherwick’s Bombay Safire Distillery directly relate each company’s production ethos within the aesthetics and manufacture of architecture. The studio developed designs for a Shapeways factory yet unlike other manufacturing companies, Shapeways does not sell a defined set of products but manufactures items on-demand that can be designed and sold by anyone. Since 2007, the 3D printing company has manufactured and sold more than ten million objects, all-the-while, only employing 22 people on its Long Island site. Economical and logistical benefits of this are self-evident, yet there is a socio-cultural impact from businesses that operate with reduced employment. How could Shapeways offset this through other activities that might provide a positive impact on the local community, and reduce the impact of automation on urban centers? Shapeways has already engaged NYC Government backed incubator activities to support the local community. The studio explores an extension of this: the addition of sponsored artist-in-residence studio spaces and a gallery-shop to provide local designers a means of access to facilities and the market, fostering greater community and human engagement.

Additive Manufactured Architecture:

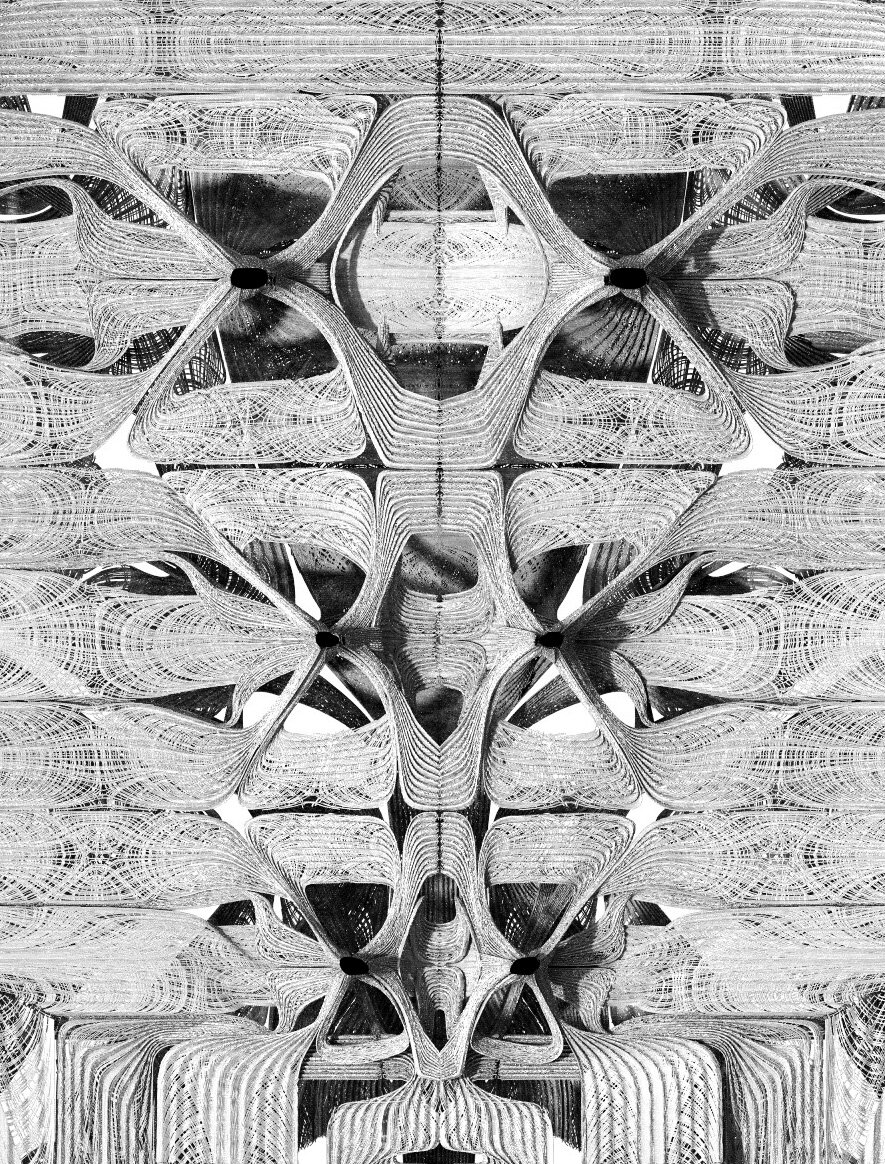

Shapeways inhabits a “Fordist”(mass-produced) building whose serial repetition, and geometrical resolution are derived from an age prior to the advent of 3d printed mass-customized production. Additive manufactured buildings have already been constructed by Winsun, Apis Khor and others in concrete, while MX3D has 3D printed a formally complex metal bridge. To date, 3D printed buildings are relatively low-resolution compared to aerospace or industrial products, or historical buildings formed in plastic materials such as reinforced concrete. Piere Luigi Nervi’s isostatic slabs seen in the Gatti Wool Factory (1951) and Manifattura Tabacchi (1952) served as precedents in the studio due to their embodiment of structural principles whilst operating as highly articulated forms of design expression. The studio commenced with structural analysis of a structural bay from some of Nervi’s projects, and development of design variations that were Topologically Structurally Optimized and analyzed to determine a relation between form, topology, structural force propagation and material grain-direction. These studies served as inspiration in projects that aimed to develop a material-order that operated in a polyvalent manner: as architectural space, form, structure and ornament, and as a wider range of aesthetic and scenario-driven properties, characteristics and affects. Polyvalent Matter investigates an Industrial architecture recast as an engaging, urban condition that incorporates both production and community activities, and articulates a mass-customized, high-resolution material-architectural order.